Grease Trap Maintenance Program

INTRODUCTION

Fats, oils, and grease (FOG) is a major concern for wastewater collection systems. When not disposed of properly, FOG forms thick layers inside sewers constricting flow, similar to the way cholesterol affects blood flow in our arteries. Clogged sewers require additional maintenance and cleaning and can result in sewage spills and overflows. FOG also places additional loadings on wastewater treatment plants, which can result in process operational difficulties, added treatment costs, and possible plant upsets. Restaurants are a significant source of FOG because of the amount of grease used in cooking and other food prep work. Improper cleanup practices allow food particles, oil, grease, and cleaning products to flow to the sanitary sewer.

Utility operation employees devote many pieces of equipment and man hours to unstopping and cleaning sanitary sewer collection systems which include, but are not limited to, manholes and gravity lines clogged with oil and grease. Ketchum municipal code 13.04.050 requires that grease traps be properly maintained.

STATEMENT OF PURPOSE

The purpose of this form is to establish a uniform policy for pumping, cleaning, maintenance, and monitoring requirements for minimizing the discharge of food waste and FOG into the wastewater collection system. The safe and efficient operation and maintenance of FOG removal devices is essential in order to properly protect the public from possible hazards caused by sanitary sewer overflows and to reduce the costs to the public and the City from clogged sewer lines due to FOG build-up.

GREASE TRAP MAINTENANCE SCHEDULE

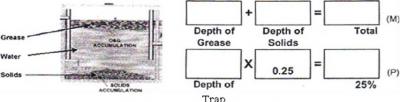

Grease traps must be cleaned when the accumulated waste, both floatable and settleable, accounts for 25 percent of its wetted depth, as measured from the static level to the interior tank bottom. The time between grease trap cleaning must not exceed any more than 90 days.

The grease trap shall be left completely empty upon completion of maintenance. All floating grease, liquids, sludge, and scrapings from the grease trap must be removed.

Under no circumstances may the removed water or materials be reintroduced into the City’s sewer system. Flushing a grease trap with hot water or the use of chemicals or other agents to dissolve or emulsify grease and allow it to flow into the wastewater treatment system is prohibited. Discharging water into a grease trap that has a temperature in excess of one hundred and forty (140) degrees F shall be strictly prohibited.

If M is greater than P. The grease trap must be cleaned. (Please refer to the image on top of page. Click to enlarge)

CLEANING GREASE TRAPS

1. Bail out any water in the trap.

2. Remove the baffles, if possible.

3. Dip the accumulated grease out of the grease trap and deposit in a watertight container.

4. Scrape the sides, lid, and baffles with a putty knife to remove as much of the grease as possible, and deposit in a watertight container.

5. Contact a hauler or recycler for grease pick up or place in trash bin for pick up.

6. Replace the baffle and the lid.

7. Record the date, employee name or company that cleaned the grease trap on your grease trap cleaning log and have it available to show the inspector upon inspection.

8. Fill out the Grease Trap Maintenance Report and submit it to the City of Ketchum.

REPORTING GREASE TRAP MAINTENANCE

Once the grease trap has been cleaned, the City Grease Trap Maintenance Report needs to be filled out and mailed or emailed to:

City of Ketchum

Attn: Collections Supervisor

P.O. Box 2315

Ketchum, ID 83340

utilities@ketchumidaho.org

Subject: Grease Trap Maintenance Report

Office (208) 726-7825